3 Reasons to Use a Plate Heat Exchanger in Plating & Anodizing

- Share on Facebook

- Share on LinkedIn

- Share on Email

-

Copy Link

-

Share Link

- Chemical

- January 23, 2019

- 1 Minute Read

- Share on Facebook

- Share on LinkedIn

- Share on Email

-

Copy Link

-

Share Link

Introduction

Effective and efficient heat exchange is crucial to plating and anodizing processes, whether in the automotive, industrial electronics, or construction industries. Solution baths require precise temperatures to ensure chemicals act as intended, creating a durable, aesthetically pleasing, and corrosion-resistant product. Plate heat exchangers are an excellent choice to drive your process in three big ways.

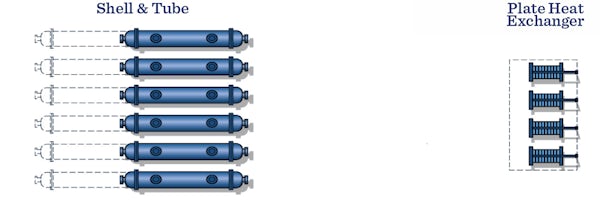

Maximizing Floor Space

Heat transfer panels inside the chemical bath may require space that could be needed for operation and solutions. Plate heat exchangers, which are located outside of the bath, act as a space saver so you can conduct plating and anodizing processes at maximum capacity externally. When compared to equivalent-capacity external types of heat exchangers, plate heat exchangers require one-fifth to one-half less floor space, efficiently optimizing your operations.

Servicing Your Chemical Bath Heat Exchanger

Internal or "in-bath" heat transfer may require the user to drain the chemical baths when it is time for maintenance. Plate heat exchangers allow the heat transfer process to occur outside of the chemical bath, allowing easy access for cleaning or maintenance work on the unit and making preventative maintenance simple to schedule. Remove the compression bolts and slide away the moveable end frame to inspect and service 100% of the heat exchanger plates. Read more about this efficient and economical PHE maintenance process.

High Efficiency Plating

Easy access to your plate heat exchanger and conserved space helps your bottom line grow. Depending on your process, Plate heat exchangers can efficiently conduct your operations by saving the time and resources it takes to service equivalent-capacity heat exchangers. Economic benefits expand even further due to higher thermal efficiency and lower manufacturing costs than in-tank heat transfer. Plate heat exchangers allow for rapid initial heat up in baths where the solution must be brought up to temperature at the beginning of a shift or at the beginning of the week.

More from Mueller Academy

- Dealer Insights from Cornes AG

- Why Direct Load Milk Is on Its Way Out

- The European Union F-Gas Regulations & Their Impact on the Refrigeration Industry

- What is the HiPerForm® Refrigeration System?

- Introducing Our New Membrane-Based Water for Injection (WFI) Skids

- Manway Gasket Installation & Bushing Adjustment

- How to Decide Between a Horizontal & Vertical Milk Tank

- MES & PSG Feedwater Quality Requirements

- On-Site Tank Fabrication Under Deadline