Why Is My Heat Transfer Leaking?

- Share on Facebook

- Share on LinkedIn

- Share on Email

-

Copy Link

-

Share Link

- Heat Transfer

- June 6, 2019

- 2 Minute Read

- Share on Facebook

- Share on LinkedIn

- Share on Email

-

Copy Link

-

Share Link

Introduction

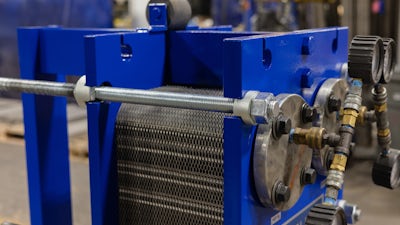

When heat transfer leaks occur, you risk contamination in your whole system. There are typically four main reasons a leak could occur: water hammering, stress corrosion cracking, overpressurizing, and lack of support.

Water Hammering

Imagine a bouncy ball in a pipe stuck between two valves bouncing back and forth. This is very similar to water hammering (or steam hammering). When a valve is closed too quickly, the pipe's contents will slam into the valve, causing a 180° energy change. This happens repeatedly, creating vibrations that travel through the pipes, which may cause cracking.

Stress Corrosion Cracking

If the media traveling through the pipes is not treated correctly, chlorides will enter the system, causing stress corrosion cracking. The build-up of corrosion products and stress can cause cracking and fatigue in the system's material. To lower the likelihood of stress corrosion cracking, the heat exchanger should not have crevices where media can become stagnant, allowing materials to accumulate.

Over Pressurizing

A heat transfer unit is designed for maximum pressure. When that maximum is exceeded, holes and cracks begin to form, allowing media to leak from the unit.

Lack of Supports

When the heat transfer unit’s connections are not properly supported, they cannot withstand the usual wear and tear imposed on the system. Think about vehicles driving across a bridge; year after year, pressure is applied to the bridge supports, causing normal wear and tear on the structure. However, if the bridge is not properly braced, then the supports will become stressed. The bridge cannot support the load traveling across it and may fail. This is similar to a heat transfer unit, but instead of vehicles traveling across a bridge, there is media flowing through the system.

Heat transfer leaks should not be taken lightly since the product within your system can become contaminated no matter what caused the leak. Regular preventative maintenance is always the best option. If your plate heat exchanger is not performing the way you expect, contact our service and repair experts.

More from Mueller Academy

- ASME Boiler and Pressure Vessel Codes

- Dealer Insights from Cornes AG

- Why Direct Load Milk Is on Its Way Out

- The European Union F-Gas Regulations & Their Impact on the Refrigeration Industry

- What is the HiPerForm® Refrigeration System?

- Introducing Our New Membrane-Based Water for Injection (WFI) Skids

- Manway Gasket Installation & Bushing Adjustment

- How to Decide Between a Horizontal & Vertical Milk Tank

- MES & PSG Feedwater Quality Requirements