-

- Up to 50% reduction in hop and adjunct use while achieving the same or better sensory analysis

- Elimination of lengthy steep times for adjuncts

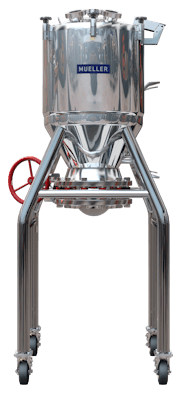

- Available in 50, 100, and 200-gallon (189.3, 378.5, and 757.1 liter) models for purchase (50 and 200 models available for Loaner Program)

- Large outlet valve allows for easy removal of spent hops and adjuncts

- Dedicated spray balls for the vessel and screen ensure complete CIP

- Motor-free design employs fluid flow to harness the essential oils and resins in hops and adjuncts while mitigating the risk of shear damage

- The configuration of the maxxLūp allows the vessel to be purged, reducing the introduction of unwanted oxygen into the product

- Removable screen design allows for thorough inspection and works with a variety of ingredients, including cone or pellet hops, coffee, spices, and fruit

- Designed for use in both cellar and brewhouse with casters that allow the user to move the vessel throughout the brewery

- Eliminates the need to access the top of the fermenter for dry hopping

- Pressure-rated and ASME Code-stamped options are available

Dry Hopping Alternative

- Pressure-rated system compatible with various adjuncts:

- Cone or pellet hops

- Coffee

- Spices

- Fruit

- Coconut

- And more

- Solves the inconvenience of traditional dry hopping processes

- More versatile than other adjunct-dosing systems on the market

- Removable screen design for efficient handling of different adjuncts

- Reported up to 50% reduction in ingredient amounts with the same or better sensory results

Infusing Spirits

- The maxxLūp infusion system works for both beer and spirits

- Ideal for industrial spirits producers seeking unique flavors and notes

- Efficient and safe flavor steeping process for spirits infusion

-

Type Density - lbs/gal (kg/L) Max Loading % Size 1: 50 Gal. (189.3 l) - lbs (kg) Size 2: 100 Gal. (378.5 l) - lbs (kg) Size 3: 200 Gal. (757.1 l) - lbs (kg) Hop Pellets 4.2 (0.5) 66% 74 (33.6) 147 (66.7) 294 (133.4) Whole Cone Hops 1.1 (0.13) 66% 36 (16.3) 72 (32.7) 143 (64.9) Coffee Beans 5.4 (0.65) 85% 230 (104.3) 459 (208.2) 918 (416.4) Vanilla Beans 2.9 (0.35) 85% 123 (55.8) 247 (112) 493 (223.6) Shredded Coconut 2.9 (0.35) 85% 123 (55.8) 247 (112) 493 (223.6) Dried-Shelled Peanuts 5.2 (0.62) 85% 221 (100.3) 442 (200.5) 884 (401) Dried Fruit 4 (0.48) 85% 170 (77.1) 340 (154.2) 680 (308.5) -

- Avery Brewing Company Case Study Download Avery Brewing Company Case Study Learn More Avery Brewing Company Case Study

- maxxLūp Hop Dosing System Sales Sheet Download maxxLūp Hop Dosing System Sales Sheet Learn More maxxLūp Hop Dosing System Sales Sheet

- MTI Shipping Solutions Brochure Download MTI Shipping Solutions Brochure Learn More MTI Shipping Solutions Brochure

- Brewing Equipment Brochure Download Brewing Equipment Brochure Learn More Brewing Equipment Brochure

- Carbonation Reference Chart Download Carbonation Reference Chart Learn More Carbonation Reference Chart

- Mueller® Capabilities Download Mueller® Capabilities Learn More Mueller® Capabilities

-

Financing Your Equipment Needs

Are you getting ready to open a a new business or are you looking to replace or expand your existing footprint? Paul Mueller Company offers a large array of products from farm to pharmaceutical and everything in between. Equipment financing is a great way to get the funds you need now without using up your credit line or working capital.

Why Finance?

- Free up working capital

- Gain tax advantages

- Match payments to cash flow

- 100% financing, including shipping and installation

- Competitive Rates

- Fast and liberal credit decisions

- Simple online application

- No obligation, no risk

- Up to 50% reduction in hop and adjunct use while achieving the same or better sensory analysis

- Elimination of lengthy steep times for adjuncts

- Available in 50, 100, and 200-gallon (189.3, 378.5, and 757.1 liter) models for purchase (50 and 200 models available for Loaner Program)

- Large outlet valve allows for easy removal of spent hops and adjuncts

- Dedicated spray balls for the vessel and screen ensure complete CIP

- Motor-free design employs fluid flow to harness the essential oils and resins in hops and adjuncts while mitigating the risk of shear damage

- The configuration of the maxxLūp allows the vessel to be purged, reducing the introduction of unwanted oxygen into the product

- Removable screen design allows for thorough inspection and works with a variety of ingredients, including cone or pellet hops, coffee, spices, and fruit

- Designed for use in both cellar and brewhouse with casters that allow the user to move the vessel throughout the brewery

- Eliminates the need to access the top of the fermenter for dry hopping

- Pressure-rated and ASME Code-stamped options are available

Dry Hopping Alternative

- Pressure-rated system compatible with various adjuncts:

- Cone or pellet hops

- Coffee

- Spices

- Fruit

- Coconut

- And more

- Solves the inconvenience of traditional dry hopping processes

- More versatile than other adjunct-dosing systems on the market

- Removable screen design for efficient handling of different adjuncts

- Reported up to 50% reduction in ingredient amounts with the same or better sensory results

Infusing Spirits

- The maxxLūp infusion system works for both beer and spirits

- Ideal for industrial spirits producers seeking unique flavors and notes

- Efficient and safe flavor steeping process for spirits infusion

| Type | Density - lbs/gal (kg/L) | Max Loading % | Size 1: 50 Gal. (189.3 l) - lbs (kg) | Size 2: 100 Gal. (378.5 l) - lbs (kg) | Size 3: 200 Gal. (757.1 l) - lbs (kg) |

|---|---|---|---|---|---|

| Hop Pellets | 4.2 (0.5) | 66% | 74 (33.6) | 147 (66.7) | 294 (133.4) |

| Whole Cone Hops | 1.1 (0.13) | 66% | 36 (16.3) | 72 (32.7) | 143 (64.9) |

| Coffee Beans | 5.4 (0.65) | 85% | 230 (104.3) | 459 (208.2) | 918 (416.4) |

| Vanilla Beans | 2.9 (0.35) | 85% | 123 (55.8) | 247 (112) | 493 (223.6) |

| Shredded Coconut | 2.9 (0.35) | 85% | 123 (55.8) | 247 (112) | 493 (223.6) |

| Dried-Shelled Peanuts | 5.2 (0.62) | 85% | 221 (100.3) | 442 (200.5) | 884 (401) |

| Dried Fruit | 4 (0.48) | 85% | 170 (77.1) | 340 (154.2) | 680 (308.5) |

- Avery Brewing Company Case Study Download Avery Brewing Company Case Study Learn More Avery Brewing Company Case Study

- maxxLūp Hop Dosing System Sales Sheet Download maxxLūp Hop Dosing System Sales Sheet Learn More maxxLūp Hop Dosing System Sales Sheet

- MTI Shipping Solutions Brochure Download MTI Shipping Solutions Brochure Learn More MTI Shipping Solutions Brochure

- Brewing Equipment Brochure Download Brewing Equipment Brochure Learn More Brewing Equipment Brochure

- Carbonation Reference Chart Download Carbonation Reference Chart Learn More Carbonation Reference Chart

- Mueller® Capabilities Download Mueller® Capabilities Learn More Mueller® Capabilities

Financing Your Equipment Needs

Are you getting ready to open a a new business or are you looking to replace or expand your existing footprint? Paul Mueller Company offers a large array of products from farm to pharmaceutical and everything in between. Equipment financing is a great way to get the funds you need now without using up your credit line or working capital.

Why Finance?

- Free up working capital

- Gain tax advantages

- Match payments to cash flow

- 100% financing, including shipping and installation

- Competitive Rates

- Fast and liberal credit decisions

- Simple online application

- No obligation, no risk