-

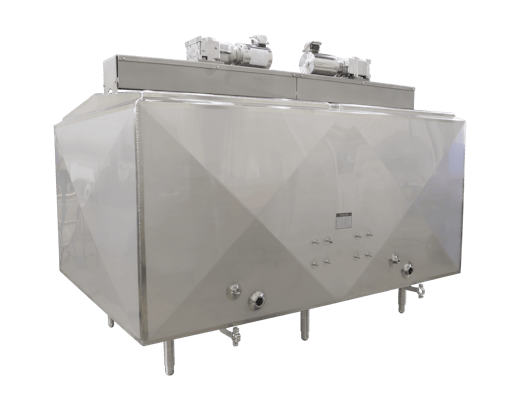

Features

- Type 304 stainless steel construction with both interior and exterior surfaces polished to a No. 4 (3-A) finish for sanitation and ease of cleaning

- Units with up to four compartments available

- Insulated adjacent compartments can be used with extreme temperature variations without appreciable heat transfer

- Stainless steel agitator shields to prevent contaminants from entering the tank

- Bottoms are pitched to an industry standard. 2" (5.1 cm) clamp-type outlet ferrule for easy, complete drainage and connection compatibility

- 1 1/2" (3.8 cm) rigid insulation on each side of each compartment

- CIP technology for quick, easy cleaning

Optional Features

- Mueller Temp-Plate® heat transfer surface designed for use with a variety of cooling and heating media, available on any or all compartments of each tank

- Calibration rod available to measure contents of each compartment

- 2" (5.1 cm) stainless steel outlet

-

Specifications

Capacity Per Unit - gal (l) Width - in (cm) Height - in (cm) Number of Compartments and Total Length - in (cm) Width of Individual Compartment - in (cm) Approx. Height with Cleaner in Place - in (cm) 1 2 3 4 100 (378.54) 41¼ (104.8) 35¼ (89.5) 30¼ (76.8) 60⅜ (153.35) 90½ (229.9) 120⅝ (306.4) 27 (68.6) 49½ (125.7) 200 (757.1) 41¼ (104.8) 46½ (118.1) 39¼ (99.7) 78⅜ (199.1) 117½ (298.5) 156⅝ (397.83) 36 (91.4) 60¾ (154.3) 300 (1,135.6) 48¼ (122.6) 51½ (130.8) 43 (109.2) 85⅞ (218.1) 128⅜ (326.1) 171⅝ (435.9) 39¾ (101) 65¼ (165.7) 400 (1,514.2) 53¼ (135.3) 52 (132.1) 50¼ (127.6) 100⅜ (255) 150½ (382.3) 200 (508) 47 (119.4) 66½ (168.9) 500 (1,892.7) 65¾ (167) 52 (132.1) 50¼ (127.6) 100⅜ (255) 150½ (382.3) 200 (508) 47 47 (119.4) 66½ (168.9) 600 (2,271.3) 78¼ (198.8) 52 (132.1) 50¼ (127.6) 100⅜ (255) 150½ (382.3) 200 (508) 47 (119.4) 66½ (168.9) 800 (3,028.3) 73⅜ (186.4) 52½ (133.4) 66⅛ (168) 132 (335.3) 197⅞ (502.6) 263¾ (669.9) 62¾ (159.4) 69¾ (177.2) 1,000 (3,785.4) 82⅜ (209.2) 60 (152.4) 66⅛ (168) 132 (335.3) 197⅞ (502.6) 263¾ (669.9) 62¾ (159.4) 74½ (189.2) -

- Mueller EU Capabilities Flyer EN Mueller Download Mueller EU Capabilities Flyer EN Mueller Learn More Mueller EU Capabilities Flyer EN Mueller

- Food and Dairy Processing Equipment Brochure - EN - Paul Mueller Company Download Food and Dairy Processing Equipment Brochure - EN - Paul Mueller Company Learn More Food and Dairy Processing Equipment Brochure - EN - Paul Mueller Company

- MTI Shipping Solutions Brochure - EN - Paul Mueller Company Download MTI Shipping Solutions Brochure - EN - Paul Mueller Company Learn More MTI Shipping Solutions Brochure - EN - Paul Mueller Company

- Mueller® Capabilities Flyer - EN - Paul Mueller Company Download Mueller® Capabilities Flyer - EN - Paul Mueller Company Learn More Mueller® Capabilities Flyer - EN - Paul Mueller Company

Features

- Type 304 stainless steel construction with both interior and exterior surfaces polished to a No. 4 (3-A) finish for sanitation and ease of cleaning

- Units with up to four compartments available

- Insulated adjacent compartments can be used with extreme temperature variations without appreciable heat transfer

- Stainless steel agitator shields to prevent contaminants from entering the tank

- Bottoms are pitched to an industry standard. 2" (5.1 cm) clamp-type outlet ferrule for easy, complete drainage and connection compatibility

- 1 1/2" (3.8 cm) rigid insulation on each side of each compartment

- CIP technology for quick, easy cleaning

Optional Features

- Mueller Temp-Plate® heat transfer surface designed for use with a variety of cooling and heating media, available on any or all compartments of each tank

- Calibration rod available to measure contents of each compartment

- 2" (5.1 cm) stainless steel outlet

Specifications

| Capacity Per Unit - gal (l) | Width - in (cm) | Height - in (cm) | Number of | Compartments | and Total | Length - in (cm) | Width of Individual Compartment - in (cm) | Approx. Height with Cleaner in Place - in (cm) |

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||||

| 100 (378.54) | 41¼ (104.8) | 35¼ (89.5) | 30¼ (76.8) | 60⅜ (153.35) | 90½ (229.9) | 120⅝ (306.4) | 27 (68.6) | 49½ (125.7) |

| 200 (757.1) | 41¼ (104.8) | 46½ (118.1) | 39¼ (99.7) | 78⅜ (199.1) | 117½ (298.5) | 156⅝ (397.83) | 36 (91.4) | 60¾ (154.3) |

| 300 (1,135.6) | 48¼ (122.6) | 51½ (130.8) | 43 (109.2) | 85⅞ (218.1) | 128⅜ (326.1) | 171⅝ (435.9) | 39¾ (101) | 65¼ (165.7) |

| 400 (1,514.2) | 53¼ (135.3) | 52 (132.1) | 50¼ (127.6) | 100⅜ (255) | 150½ (382.3) | 200 (508) | 47 (119.4) | 66½ (168.9) |

| 500 (1,892.7) | 65¾ (167) | 52 (132.1) | 50¼ (127.6) | 100⅜ (255) | 150½ (382.3) | 200 (508) | 47 47 (119.4) | 66½ (168.9) |

| 600 (2,271.3) | 78¼ (198.8) | 52 (132.1) | 50¼ (127.6) | 100⅜ (255) | 150½ (382.3) | 200 (508) | 47 (119.4) | 66½ (168.9) |

| 800 (3,028.3) | 73⅜ (186.4) | 52½ (133.4) | 66⅛ (168) | 132 (335.3) | 197⅞ (502.6) | 263¾ (669.9) | 62¾ (159.4) | 69¾ (177.2) |

| 1,000 (3,785.4) | 82⅜ (209.2) | 60 (152.4) | 66⅛ (168) | 132 (335.3) | 197⅞ (502.6) | 263¾ (669.9) | 62¾ (159.4) | 74½ (189.2) |

- Mueller EU Capabilities Flyer EN Mueller Download Mueller EU Capabilities Flyer EN Mueller Learn More Mueller EU Capabilities Flyer EN Mueller

- Food and Dairy Processing Equipment Brochure - EN - Paul Mueller Company Download Food and Dairy Processing Equipment Brochure - EN - Paul Mueller Company Learn More Food and Dairy Processing Equipment Brochure - EN - Paul Mueller Company

- MTI Shipping Solutions Brochure - EN - Paul Mueller Company Download MTI Shipping Solutions Brochure - EN - Paul Mueller Company Learn More MTI Shipping Solutions Brochure - EN - Paul Mueller Company

- Mueller® Capabilities Flyer - EN - Paul Mueller Company Download Mueller® Capabilities Flyer - EN - Paul Mueller Company Learn More Mueller® Capabilities Flyer - EN - Paul Mueller Company