-

Features

- Contains up to 200 herringbone pattern embossed plates of stainless steel construction

- Intersecting ridges of adjacent plates create a compact, pressure-resistant heat transfer process.

- Allows for the design of more compact engineering systems

- Provides a cost-effective, superior solution to your heat transfer applications

- Reduces cooling media volume, further reducing the cost of fluid handling systems and energy consumption

-

Specifications

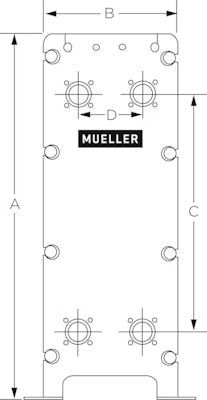

Model Number A - in (cm) B - in (cm) C - in (cm) D - in (cm) Port Size - in (cm) Max Flow Rate - gpm (lpm) LA14 8.0 (20.3) 3.2 (8.1) 6.5 (16.4) 1.7 (4.2) 0.75 (1.9) 30 (114) LA22 11.8 (29.9) 3.2 (8.1) 10.2 (26.0) 1.7 (4.2) 0.75 (1.9) 30 (114) LA34 18.5 (47.1) 3.2 (8.1) 17.0 (43.2) 1.7 (4.2) 0.75 (1.9) 30 (114) LB31 11.3 (28.6) 4.8 (12.3) 9.1 (23.2) 2.7 (6.8) 1 (2.5) 50 (189) LB47 16.4 (41.7) 4.8 (12.3) 14.2 (36.0) 2.7 (6.8) 1 (2.5) 50 (189) LB60 21.2 (53.8) 4.8 (12.3) 18.9 (48.0) 2.7 (6.8) 1 (2.5) 50 (189) LM110 24.4 (62.0) 7.5 (19.1) 20.5 (52.0) 3.6 (9.1) 2 (5.1) 200 (757) LC110 18.4 (46.6) 10.2 (25.8) 14.9 (37.8) 6.7 (17.0) 2.5 (6.4) 300 (1,136) LC170 27.1 (68.8) 10.2 (25.8) 23.6 (60.0) 6.7 (17.0) 2.5 (6.4) 300 (1,136) LD235 31.0 (78.8) 12.2 (31.0) 26.9 (68.2) 8.0 (20.4) 3 (7.6) 450 (1,703) LE400 39.7 (100.8) 15.2 (38.7) 33.9 (86.1) 9.4 (24.0) 4 (10.2) 800 (3,028) LF700 52.24 (132.7) 21.73 (55.2) 43.31 (110.0) 12.8 (32.5) 6 (15.2) 1800 (6,814) -

- Heat Transfer Solutions Brochure - EN - Paul Mueller Company Download Heat Transfer Solutions Brochure - EN - Paul Mueller Company Learn More Heat Transfer Solutions Brochure - EN - Paul Mueller Company

- Mueller EU Capabilities Flyer EN Mueller Download Mueller EU Capabilities Flyer EN Mueller Learn More Mueller EU Capabilities Flyer EN Mueller

- MTI Shipping Solutions Brochure - EN - Paul Mueller Company Download MTI Shipping Solutions Brochure - EN - Paul Mueller Company Learn More MTI Shipping Solutions Brochure - EN - Paul Mueller Company

- Refrigeration Products Catalog - EN - Paul Mueller Company Download Refrigeration Products Catalog - EN - Paul Mueller Company Learn More Refrigeration Products Catalog - EN - Paul Mueller Company

- Accu-Therm® Plate Heat Exchangers Brochure - EN - Paul Mueller Company Download Accu-Therm® Plate Heat Exchangers Brochure - EN - Paul Mueller Company Learn More Accu-Therm® Plate Heat Exchangers Brochure - EN - Paul Mueller Company

- Mueller® Capabilities Flyer - EN - Paul Mueller Company Download Mueller® Capabilities Flyer - EN - Paul Mueller Company Learn More Mueller® Capabilities Flyer - EN - Paul Mueller Company

Features

- Contains up to 200 herringbone pattern embossed plates of stainless steel construction

- Intersecting ridges of adjacent plates create a compact, pressure-resistant heat transfer process.

- Allows for the design of more compact engineering systems

- Provides a cost-effective, superior solution to your heat transfer applications

- Reduces cooling media volume, further reducing the cost of fluid handling systems and energy consumption

Specifications

| Model Number | A - in (cm) | B - in (cm) | C - in (cm) | D - in (cm) | Port Size - in (cm) | Max Flow Rate - gpm (lpm) |

|---|---|---|---|---|---|---|

| LA14 | 8.0 (20.3) | 3.2 (8.1) | 6.5 (16.4) | 1.7 (4.2) | 0.75 (1.9) | 30 (114) |

| LA22 | 11.8 (29.9) | 3.2 (8.1) | 10.2 (26.0) | 1.7 (4.2) | 0.75 (1.9) | 30 (114) |

| LA34 | 18.5 (47.1) | 3.2 (8.1) | 17.0 (43.2) | 1.7 (4.2) | 0.75 (1.9) | 30 (114) |

| LB31 | 11.3 (28.6) | 4.8 (12.3) | 9.1 (23.2) | 2.7 (6.8) | 1 (2.5) | 50 (189) |

| LB47 | 16.4 (41.7) | 4.8 (12.3) | 14.2 (36.0) | 2.7 (6.8) | 1 (2.5) | 50 (189) |

| LB60 | 21.2 (53.8) | 4.8 (12.3) | 18.9 (48.0) | 2.7 (6.8) | 1 (2.5) | 50 (189) |

| LM110 | 24.4 (62.0) | 7.5 (19.1) | 20.5 (52.0) | 3.6 (9.1) | 2 (5.1) | 200 (757) |

| LC110 | 18.4 (46.6) | 10.2 (25.8) | 14.9 (37.8) | 6.7 (17.0) | 2.5 (6.4) | 300 (1,136) |

| LC170 | 27.1 (68.8) | 10.2 (25.8) | 23.6 (60.0) | 6.7 (17.0) | 2.5 (6.4) | 300 (1,136) |

| LD235 | 31.0 (78.8) | 12.2 (31.0) | 26.9 (68.2) | 8.0 (20.4) | 3 (7.6) | 450 (1,703) |

| LE400 | 39.7 (100.8) | 15.2 (38.7) | 33.9 (86.1) | 9.4 (24.0) | 4 (10.2) | 800 (3,028) |

| LF700 | 52.24 (132.7) | 21.73 (55.2) | 43.31 (110.0) | 12.8 (32.5) | 6 (15.2) | 1800 (6,814) |

- Heat Transfer Solutions Brochure - EN - Paul Mueller Company Download Heat Transfer Solutions Brochure - EN - Paul Mueller Company Learn More Heat Transfer Solutions Brochure - EN - Paul Mueller Company

- Mueller EU Capabilities Flyer EN Mueller Download Mueller EU Capabilities Flyer EN Mueller Learn More Mueller EU Capabilities Flyer EN Mueller

- MTI Shipping Solutions Brochure - EN - Paul Mueller Company Download MTI Shipping Solutions Brochure - EN - Paul Mueller Company Learn More MTI Shipping Solutions Brochure - EN - Paul Mueller Company

- Refrigeration Products Catalog - EN - Paul Mueller Company Download Refrigeration Products Catalog - EN - Paul Mueller Company Learn More Refrigeration Products Catalog - EN - Paul Mueller Company

- Accu-Therm® Plate Heat Exchangers Brochure - EN - Paul Mueller Company Download Accu-Therm® Plate Heat Exchangers Brochure - EN - Paul Mueller Company Learn More Accu-Therm® Plate Heat Exchangers Brochure - EN - Paul Mueller Company

- Mueller® Capabilities Flyer - EN - Paul Mueller Company Download Mueller® Capabilities Flyer - EN - Paul Mueller Company Learn More Mueller® Capabilities Flyer - EN - Paul Mueller Company

Applications

Brazed plate heat exchangers can be used for a variety of applications, including:

- Condensers

- Heat Pump

- Air Conditioning

- Refrigerant

- Chiller

- Evaporators

- Subcoolers

- Oil coolers