-

Modularity

- Includes RO pre-filter, dual RO pumps, RO housings and membranes, and CEDI

- Designed to be fed with softened, chlorine/chloride-free water

- Available as a standalone unit or as part of a larger integrated system

- System can be oversized to branch off the RO or softener to feed other facility utilities

- All stainless steel tubing

- One centrally-located UL 508A-certified control system

- Distributed I/O capabilities

- Industrial-hardened Ethernet backbone

- Fully supported by factory-certified service technicians

- Supported by our in-house ISO 17025 calibration lab with onsite services

Designed for Sustainability

- Designed for pharmaceutical applications, including hot water sanitizable RO membranes

- Integrated control system manages the entire system and interfaces with other Mueller water and steam systems

- Requires no plant steam or coolant

- Includes water recycling to reduce waste

Standard Features

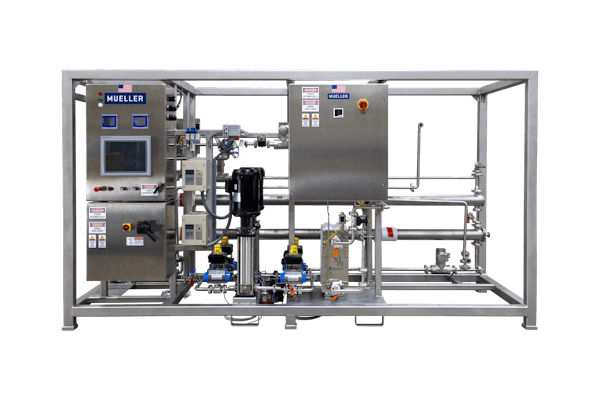

- Fully operational, skidded, and factory-tested

- Reduces start-up time and site installation effort

- Includes full turnover package (TOP)

- Stainless steel tubing 25RA (SF2) for RO system

- Fully schedulable hot water sanitizable standard for RO system

- Full perimeter stainless steel framing for protection and easy installation

- Adjustable feet for leveling during installation

- Backed by warranty

- Common, off-the-shelf control system

- Redundant RO feed pumps for reliability

Customizable Features

- Component manufacturers

- Programming

- Additional or limited instrumentation

- Network interfacing

- Sanitization methods

- Interface with other Mueller equipment

- Power input capabilities

- UPS capabilities

-

Sizes

- 5, 10, 20, 30, and 50 gpm (18.9, 37.9, 75.7, 113.6, and 189.3 lpm) RO/CEDI systems

- Custom sizes available upon request

Models

- RO-5 through 50

-

- Mueller EU Capabilities Flyer EN Mueller Download Mueller EU Capabilities Flyer EN Mueller Learn More Mueller EU Capabilities Flyer EN Mueller

- Reverse Osmosis (RO) and Continuous Electrodeionization (CEDI) Skid Flyer - EN - Paul Mueller Company Download Reverse Osmosis (RO) and Continuous Electrodeionization (CEDI) Skid Flyer - EN - Paul Mueller Company Learn More Reverse Osmosis (RO) and Continuous Electrodeionization (CEDI) Skid Flyer - EN - Paul Mueller Company

- Pharmaceutical Solutions Brochure - EN - Paul Mueller Company Download Pharmaceutical Solutions Brochure - EN - Paul Mueller Company Learn More Pharmaceutical Solutions Brochure - EN - Paul Mueller Company

- Pharmaceutical Solutions Brochure - EN - Mueller Download Pharmaceutical Solutions Brochure - EN - Mueller Learn More Pharmaceutical Solutions Brochure - EN - Mueller

- MTI Shipping Solutions Brochure - EN - Paul Mueller Company Download MTI Shipping Solutions Brochure - EN - Paul Mueller Company Learn More MTI Shipping Solutions Brochure - EN - Paul Mueller Company

- Mueller® Capabilities Flyer - EN - Paul Mueller Company Download Mueller® Capabilities Flyer - EN - Paul Mueller Company Learn More Mueller® Capabilities Flyer - EN - Paul Mueller Company

Modularity

- Includes RO pre-filter, dual RO pumps, RO housings and membranes, and CEDI

- Designed to be fed with softened, chlorine/chloride-free water

- Available as a standalone unit or as part of a larger integrated system

- System can be oversized to branch off the RO or softener to feed other facility utilities

- All stainless steel tubing

- One centrally-located UL 508A-certified control system

- Distributed I/O capabilities

- Industrial-hardened Ethernet backbone

- Fully supported by factory-certified service technicians

- Supported by our in-house ISO 17025 calibration lab with onsite services

Designed for Sustainability

- Designed for pharmaceutical applications, including hot water sanitizable RO membranes

- Integrated control system manages the entire system and interfaces with other Mueller water and steam systems

- Requires no plant steam or coolant

- Includes water recycling to reduce waste

Standard Features

- Fully operational, skidded, and factory-tested

- Reduces start-up time and site installation effort

- Includes full turnover package (TOP)

- Stainless steel tubing 25RA (SF2) for RO system

- Fully schedulable hot water sanitizable standard for RO system

- Full perimeter stainless steel framing for protection and easy installation

- Adjustable feet for leveling during installation

- Backed by warranty

- Common, off-the-shelf control system

- Redundant RO feed pumps for reliability

Customizable Features

- Component manufacturers

- Programming

- Additional or limited instrumentation

- Network interfacing

- Sanitization methods

- Interface with other Mueller equipment

- Power input capabilities

- UPS capabilities

Sizes

- 5, 10, 20, 30, and 50 gpm (18.9, 37.9, 75.7, 113.6, and 189.3 lpm) RO/CEDI systems

- Custom sizes available upon request

Models

- RO-5 through 50

- Mueller EU Capabilities Flyer EN Mueller Download Mueller EU Capabilities Flyer EN Mueller Learn More Mueller EU Capabilities Flyer EN Mueller

- Reverse Osmosis (RO) and Continuous Electrodeionization (CEDI) Skid Flyer - EN - Paul Mueller Company Download Reverse Osmosis (RO) and Continuous Electrodeionization (CEDI) Skid Flyer - EN - Paul Mueller Company Learn More Reverse Osmosis (RO) and Continuous Electrodeionization (CEDI) Skid Flyer - EN - Paul Mueller Company

- Pharmaceutical Solutions Brochure - EN - Paul Mueller Company Download Pharmaceutical Solutions Brochure - EN - Paul Mueller Company Learn More Pharmaceutical Solutions Brochure - EN - Paul Mueller Company

- Pharmaceutical Solutions Brochure - EN - Mueller Download Pharmaceutical Solutions Brochure - EN - Mueller Learn More Pharmaceutical Solutions Brochure - EN - Mueller

- MTI Shipping Solutions Brochure - EN - Paul Mueller Company Download MTI Shipping Solutions Brochure - EN - Paul Mueller Company Learn More MTI Shipping Solutions Brochure - EN - Paul Mueller Company

- Mueller® Capabilities Flyer - EN - Paul Mueller Company Download Mueller® Capabilities Flyer - EN - Paul Mueller Company Learn More Mueller® Capabilities Flyer - EN - Paul Mueller Company