Bakery Water Chilling

Conquer Cooling Demands

We provide complete bakery water chilling solutions. Our expertise, built over 80+ years, makes us confident we can help you select the best equipment to meet your craft, commercial, or industrial bakery water chilling demands. When you consult our experts, we partner with you to assess the efficiency of your operation, review your current resources, and find the most suitable solution to support your unique operation. Mueller® bakery water chilling equipment helps you deliver a quality product that always looks and tastes delectable.

Each Batch Consistently Cool

Bakers know chillers and cooling equipment are employed to cool the dough, retard the yeast, and slow down the dough-rising process. The slower the yeast works during fermentation, the more enzymes it can create to convert starch to sugar, making the dough easier to handle. This practice helps bakers avoid air pockets and supports consistent results in each batch. The ability to lengthen fermentation times lets bakers create a broad spectrum of flavor profiles suited to each baked good.

We use flexibility as we develop your personalized bakery water chilling solution. Still, the general guidelines listed below help define your project's scope and determine your specific batch water cooling equipment needs.

Craft Bakery Water Chilling

For Bakeries Requiring 10 to 70 Gallons (37.9 to 265 Liters) of Chilled Water Per Hour

Mueller bakery or batch water chillers for bakery applications lay the foundation for our craft bakery water chilling solution in operations requiring 10 to 70 gallons (37.9 to 265 liters) of chilled water per hour. A typical implementation involves a single point of use, often in conjunction with an E-Star® OE condensing unit, but chillers can be tied into a centralized refrigeration rack for supermarket applications.

Our batch-cooling water chillers for bakery applications deliver automatic water temperature control, so you experience consistent cooling and temperature maintenance in every batch of dough, no matter the setting or season. Mueller bakery batch water chillers have built-in freeze protection, so you no longer have to worry about chiller freeze-up. Our units provide up to 70 gallons (265 liters) of chilled water per hour, with 50 to 120 gallon (189.3 to 454.3 liter) storage capacities available.

Most competitors make the mistake of filling during the draw, causing temperatures to rise. Mueller bakery chillers and batch water chillers for bakery applications are true batch chillers, ensuring consistent temperatures. A uniform water draw is essential to prevent the blending of water temperatures during the batch cooling process. As you pull a draw, no new water is allowed into the chiller from the beginning to the end of the draw.

Mueller batch cooling water chillers are used throughout the baking industry to make pretzels and other pastries, bread, pizza dough, tortillas, and more. They are also ideal for any operation that requires cool ingredient water for batch processes, such as dry ingredients and liquid foods.

Commercial Bakery Water Chilling

For Bakeries Requiring 70 to 288 Gallons (265 to 1,090.2 Liters) of Chilled Water Per Hour

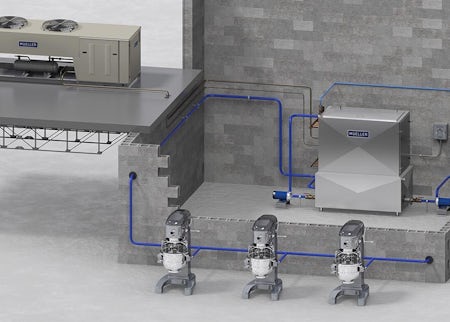

Our commercial bakery water chilling solution is aimed at bakeries demanding 70 to 288 gallons (265 to 1,090.2 liters) of chilled water per hour. This solution works for single or multiple-mixer bakeries. Frequently employed cooling equipment includes batch water chillers for bakery applications (also referred to as quad-plate chillers), 3x3 falling film chillers, and the E-Star OE condensing unit.

The E-star OE condensing unit, frequently used in the commercial bakery water chilling solution, has a proprietary accumulator heat exchanger, which maximizes refrigeration capacity while protecting the compressor from liquid refrigerant. The unit, prized for its quiet, energy-efficient Copeland "ZB" scroll compressor, is designed for commercial refrigeration service rather than air conditioning. It provides improved performance over the entire cooling temperature range.

Industrial Bakery Water Chilling

For Bakeries Requiring 240 Gallons (908.5 Liters) of Chilled Water Per Hour and Up

The industrial bakery water chilling solution is well-suited for bakeries requiring 240 gallons (908.5 liters) of chilled water per hour or more. The solution is appropriate for multiple points of use and compatible with existing centralized refrigeration systems using Freon or ammonia refrigerants.

Ideal for the increased demands of industrial bakery water chilling, Mueller's self-contained, air-cooled refrigeration unit delivers a cooling punch, reduces energy usage, and increases efficiency in your bakery. Equipped with the Mueller Multi-Stage chiller control, it lets you set the unit to cycle on and off based on your water flow. Real-time water temperatures sensed by the Multi-Stage chiller control engage only the components necessary to perform your cooling at each specific moment.

For industrial bakeries desiring robust cooling support from our product lineup, we offer the Mueller 3x5 and 4x8 falling film chillers to fortify chilling efforts. These units deliver the cooling boost your operation needs. The practical design of these falling film chillers makes them easy to clean and inspect with almost no downtime for maintenance. Mueller Temp-Plate® panels inside eliminate the possibility of chiller freeze-up, and they accept incoming fluid temperatures up to 105°F without needing a secondary heat exchanger.

Designed for large-capacity water chilling applications, the fully enclosed construction of the 3x5 and 4x8 falling film chillers eliminates product contamination by ensuring your product is free from airborne particles. Interiors are easily accessible through gasketed doors. Customize your cabinet with additional plates (up to cabinet capacity) while selecting a cabinet that allows for future expansion as your operation grows.

Keep Your Cool with Mueller Chillers

Our team of certified service technicians provides around-the-clock U.S. technical support. Do you have a question about commercial bakery chilling equipment? Consult our dedicated service and sales teams when sizing equipment, during chiller installation, or with maintenance questions. Trusted partners and expert guides, we are committed to helping you run a smooth operation.

Features at a Glance

- Replacement parts readily available

- Precise temperature control

- Outlet temps down to 34°F (1.1°C)

- U.S. technical support

- Inlet temps up to 105°F (40.6°C)

- True batch chillers

- Made in the USA

- ETL-Listed