Transformation of the Robotic Dairy

Robotic dairies have been around for nearly twenty years now, and this progressive method of milk harvesting has slowly taken a strong hold on the industry. The first dairy producers who stepped out of the norm have now lived through several years of automated milking. Their experiences are now encouraging growth: more cows, more robots, and another Mueller® milk cooler.

Benefits of Dual Milk Coolers

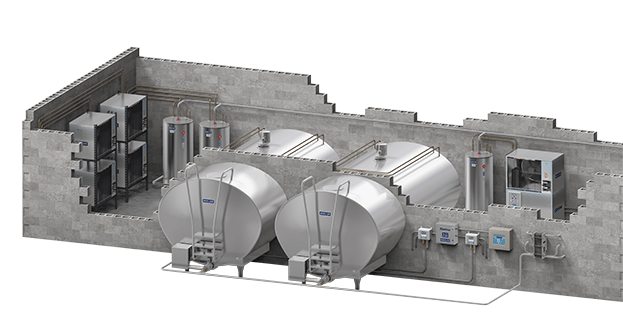

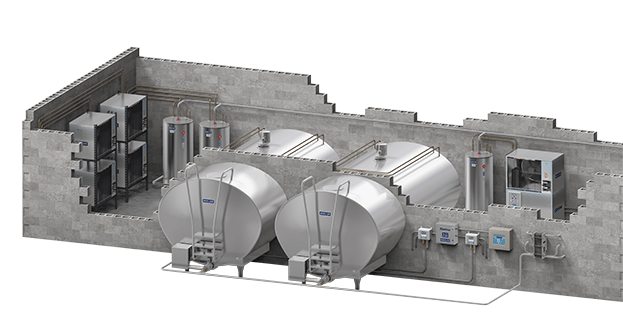

Are you thinking of using four or more robots? Then you should plan on using two Mueller milk coolers. Multiple milk coolers have several benefits, and milk quality is at the top of the list. With two milk coolers, there is no need to rush the milk hauler sampling process or reduce wash time to prevent the buffer tank from overflowing. Milk sampling and wash cycle procedures are among the most crucial safeguards for your milk quality--and wallet. Dual milk coolers also help automate your milk house and allow a more flexible pickup schedule for your hauler. Mueller’s large robotic cooling control, Nimbus™, lets you switch between milk coolers with an adjustable setpoint based on milk volume and stream live milk temperatures and volumes on your smartphone from anywhere you have cellular data access.

Utilize Cooling Capacity

When milking into multiple milk coolers, sharing refrigeration is essential. The HiPerChill™ 5 cools milk before it enters your milk coolers, ensuring the highest quality product from your robotic dairy. It utilizes the same Mueller HiPerForm® technology the dairy industry has relied on for over 40 years. A high-efficiency E-Star® condensing unit, brazed plate heat exchanger, circulation pump, and reservoir are all housed inside the HiPerChill 5, resulting in a compact package chiller able to deliver a higher cooling capacity over a broader range of temperatures than conventional direct expansion refrigeration systems. The HiPerChill 5 also works in unison with an Accu-Therm® plate cooler to instant cool milk in the transfer line as it exits your robotic milking stalls. Refrigeration at the milk cooler then maintains a desired low setpoint.

Built for Expansion

As dairy producers think long term about future growth, you will likely see more robotic dairies worldwide. Robotic dairies allow dairy producers more time for things they are passionate about, such as herd health, milk quality, and genetics. This way of life also promotes flexibility in a dairy producer's daily operations and means more quality time with family and friends. At Paul Mueller Company, we are here to support your efforts with the most efficient milk storage and cooling equipment available. When designing a robotic dairy farm, request a cooling solution consultation with your local authorized Mueller dealer.